Integration of sensitive HDDs into rough target systems

HDDs are sensitive against external excitation such as system fans, neighborhood HDDs or any other system induced noise. I/O performance is compromised unintentionally or data loss remains inexplicable. Here is an overview of such mechanism and how to counteract.

How to seamlessly integrate HDDs in rough target systems? It´s one of the toughest challenges out there. The Rotational Vibration (RV) factor does require lots of system- AND component design experience, and with each new HDD generation it´s getting more complex.

Especially high capacitive HDDs in 3.5” form factor are getting more and more sensitive for external and internal source of RV energy levels.

System mechanical designer will state, that the HDDs getting to sensitive, while HDD makers will assure, that system fans and -chassis or cage designs need to improve.

As always, truth lives in the middle of both, not a surprise.

Before going into the details for best practice introduction methodologies, let´s quickly

cover what´s happening:

So the front site of the HDD is moving relative to the interface connector in direction of the second longest axis of a hard drive forth and back. In a first approach the interface connector does not move at all, so it´s a tiny mechanical spacing of a circular path.

Depending the frequency such movement happens, it´s almost not even noticeable for the human eyes.

Root causes if RV energy levels are quite different in frequency and energy levels. Very typical are some pure tones within the system design for sure: system fans and mechanical given resonances of cages and cabinets and a few others. Also, HDDs in the direct neighborhood do interact sometimes with hard drives, not to forget the internal excitations during seeking operations of a HDD itself.

As any given mechanical design, also the Head Disk Assembly (HDA, for Japanese Vendors: DE = Disk Enclosure) does have its own resonance frequencies. Depending the vendor and model the susceptibility can vary very much.

Effects of a RV caused system deterioration are I/O performance loss for sequential- and random write I/O’s and also compromise of data integrity. Also after exhibiting a HDD under high RV energy levels during writes, a later on sequential read will lose I/O performance values as well, “rough” written tracks can cause – 20% of lower sequential read performance though.

If the data heads of the HDD are forced by the RV energy level to move too much off-track, still in the detection range of the write-inhibit circuitry, there is a chance to remain unable to read back the user data affected, those data will be gone.

Solving such a challenging issue is typically very time consuming, hence either the system maker should improve his mechanical design or the HDD vendor has to incorporate another digital servo notch filter to reduce susceptibility at a given frequency range. That again underpins the fact to find such a scenario as early as possible within the “bring-to-market” process.

In many cases this kind of component-system interaction remains invisible to the outer world, I/O performance gets slower for unknown reasons, error recovery processes are invoked more often or even there is “silent” data loss going on, assuming the “marginal” write process is not directly followed by a read back process right after.

Recent observations show the classic case: system fans rotate at a frequency or (sub-) harmonics where the installed HDDs are susceptible on.

TECODI had undergone a systematic analysis of such phenomena and designed a test procedure as part of the overall system integration work, which allows to detect such overlapping situations from HDDs and target system.

The RV Fragility Boundary Testing (RV FBT) is a target-system-independent test suite for HDDs which shows as the test result the susceptibility structure of the HDD under test. There are drive designs out there which have higher or lower susceptibility in direct comparison to each other.

The quantified test documentation shows the susceptible areas and corresponding energy levels which the HDD can tolerate without losing predefined I/O performance levels and maintain data integrity.

Pic 1: RV FBT test suite cover sheet

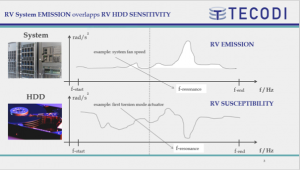

To illustrate an example for the above, below is a sketch showing an overlap condition:

The system does show at a given frequency an elevated RV energy emission, whereas the HDD under test is susceptible for.

Pic 2: Overlapping of emitted and susceptible frequency

The main part of the RV FBT test suite is the RVC400 RV shaker table, which is controlled by a mechanical regulation system as a loop back system and an own developed software program controlling the next step of the testing. While exposed to such RV excitation, the HDD under test is doing some very dedicated read/write I/O’s.

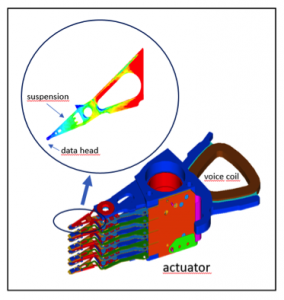

Each and any HDD has its unique sensitive frequency areas, for instance the diagonal of the diecast HDA is half wavelength of a very predominant resonance frequency. There are even own names for such phenomena like deck mode or rock modes, or as for the actuator, the industry talks about butterfly or lean modes of the positioning unit, the suspension does have its own first and second torsion modes and so on.

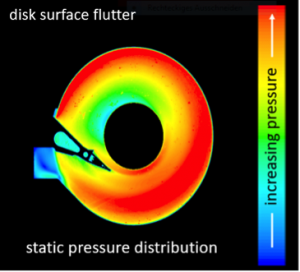

Especially for the 3.5” form factor HDDs, the outer zones of the media at the outer diameter (OD), have a tendency to show disk flutter, which are some predominant swing modes at firm frequencies derived from the geometry of the physics.

Stimulating such frequencies from any source of excitation, the result can be as severe as a Head Disk Interference (HDI), which may eventually last another couple of power on hours before the drive finally dies.

Pic 4: disk flutter at the OD radius

A given typical HDD does exhibit in the order of 15 and more different resonances, some more some less susceptible. A good number of digital notch filters are acting on those for sure, but depending the overall HDD design, there can be very easily an aggravated sensitivity of such HDD.

Pic 5: first torsion mode of the suspension

Depending the vendor and the model under test, the modes can eventually toggle, where the odd harmonics are the more relevant ones to control.

TECODI does work very close and committed with the majority of the HDD vendors and system integrators as well as manufacturers of elastomers to eliminate or at least minimize the overall impact of RV issues in a given customer system.

As a future looking statement, HDD designs with even higher TPI / BPI areal densities, will show more of these susceptibilities in terms of RV energy. So, for your own safety, it´s good to understand the sensitivity of a new HDD upfront and for sure, have an early guideline, where your target system is emitting RV energy levels, to avoid any of those overlapping scenarios.

Thera re good news, HELIUM filled HDAs will help to push out these critical scenarios for some

time, but will remain unable to fully eliminate those.

Other approaching technologies such as HAMR, Thermal Media Heating (THM) or Shingled Media Recording (SMR, overlapping data tracks) will be a challenge for the RV integration.

TECODI-early detection means early elimination.